So many features,

so very small

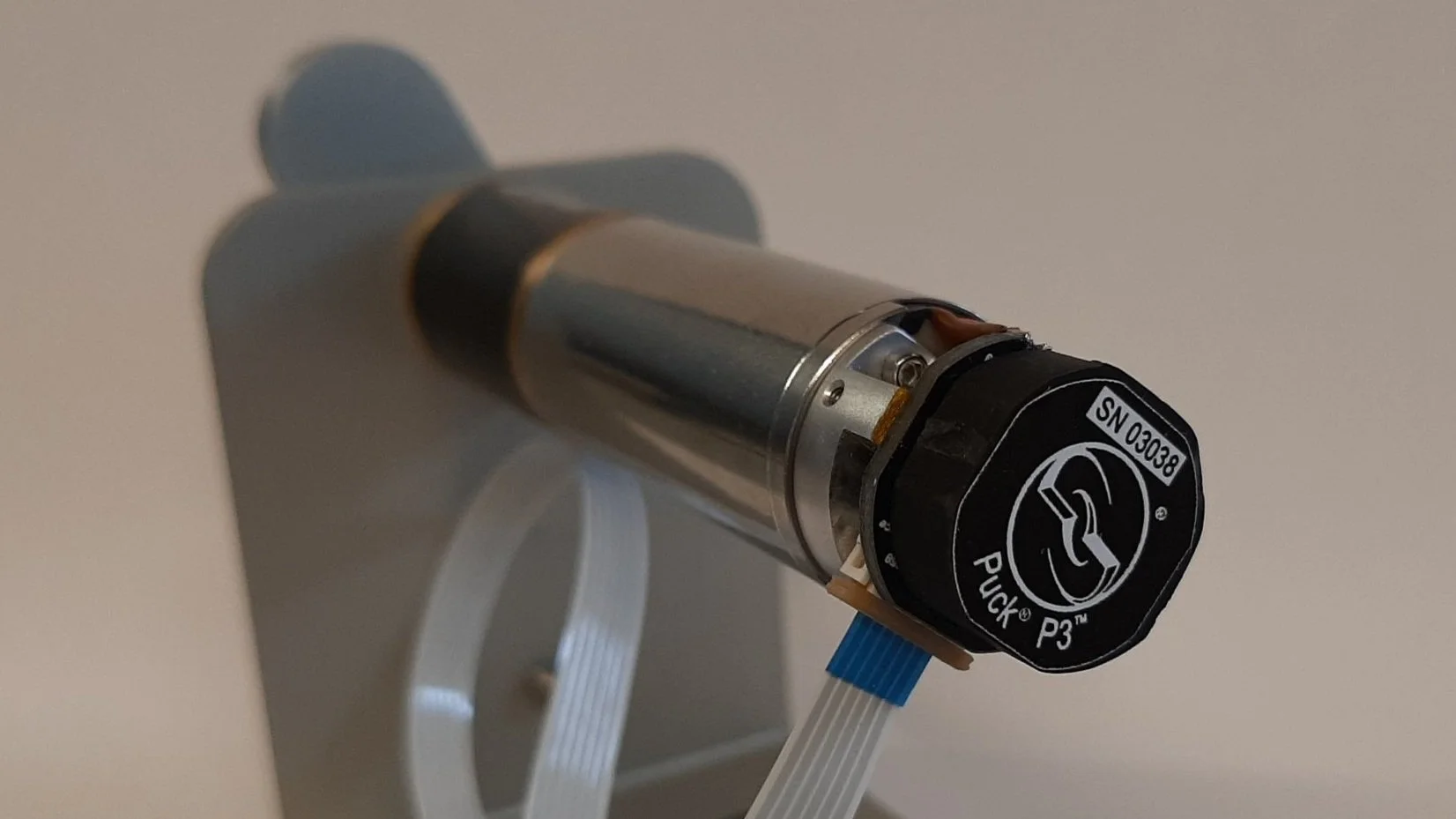

The Puck® P3™ is an ultra-miniature, high-performance brushless servomotor controller that simplifies complex multi-actuator designs!

It is easily integrated into any application requiring maximum power efficiency, low mass, and compact size. The revolutionary Puck® P3™ is networked with an integrated encoder and precision current sensor. It controls the torque output of a brushless servomotor with state-of-the-art space-vector commutation and low torque ripple.

• An all-in-one solution

• Built-in encoder eliminates wiring rat’s nest

• 6X smaller than the next-smallest competitor

Check out our Industrial Robotics YouTube channel→

Features and Specifications

Quiet, fanless operation

Internal temperature sensing

In-system field-upgradeable firmware

(Optional) Digital Hall-effect inputs

Adjustable PWM frequency

Motor-temperature sensing

Dual analog inputs (16-bit)

Up to 4 digital I/O

External encoder capable:

SPI or quadratureSPI master peripheral support

High-speed CANopen communication with software-controllable termination resistor

4 (or optionally 5)-wire bus topology: 2-wire CAN, Motor power 12-50 vdc, Ground, Logic power (optional)

Up to 31 controllers/bus

Built-in magnetic encoder (absolute, 0.1° precision)

5- and 3.3-vdc auxiliary outputs

Integrated current sensing

Space-vector commutation

32-bit floating-point processor

Low torque ripple

Competitor Comparisons

The Puck® P3™ is a networkable high-performance brushless single-axis motion controller and amplifier with an integrated encoder and precision current sensing. It controls the torque output of a brushless servomotor with state-of-the-art space-vector commutation and low torque ripple. You can also command velocity, position, or give the controller a target position to reach using its built-in trapezoidal velocity controller.

P3 is the product of two decades of design, development, testing, and refinement of the motor controllers used in our own robots. With a volume of only 1.9 cm3 and a total weight of only 4 grams, Puck® P3™ is designed to replace a standard motion controller and amplifier while taking up less space than a typical encoder. When mounted directly onto the motor body, the close proximity of the controller eliminates the encoder-to-controller wiring issues encountered with standard motion-control setups such as wire routing, connectoritus, signal degradation, EMI, I²R power losses, and cable bulk.

Up to 31 P3s may be networked together on a single, easy to manage, 4- or (optionally) a 5-wire bus. Two wires are used for robust, industry-standard CANopen communications. One wire supplies motor power, one wire is a ground, and an optional 5th wire can supply logic power separately.

Puck® P3™ controls a wide range of motor voltages from 16 to 50 vdc without any reconfiguration. It is designed to command a smooth, continuous torque, even when the input voltage is unstable.

Please contact Barrett's experts at sales@barrett.com to see if the Puck® P3™ is a good solution for your OEM application